Incyanity Yarn Update

On June 28, 2020, Incyanity was rebranded as aka Iron Dragon.

Read the announcement.

I originally announced my new yarn venture at the end of May. Now it’s September! Time has really flown by. I’ve been working on my yarn and some folks have been asking when the store will be open, so I wanted to post an update to let everyone know where things are at.

I’ve run a home-based business before (close to 20 years ago now, yikes) but that was a whole different ball of wax compared to this! Back then I was freelance editing science fiction and fantasy novels which meant I didn’t have to worry so much about a tangible product—because the “product” I was selling was me, and all the work I did was completed via email. Having a portfolio website with testimonials and some referrals was just about all I needed. For dyeing? There has to be actual yarn! Shipping agreements! Shipping supplies! And so on and so forth. There are a lot of things I still have to take care of to make sure everything is on the up and up. But, obviously, the most important thing for customers is the yarn.

During the heaviest part of my research phase, I came across some horror stories about dyers who had initially been really gung-ho about their new business but then had everything blow up in their faces. They opened their shop, started taking orders, and thought everything was going great—right up until they suddenly couldn’t dye enough yarn to meet demand. These dyers were doing preorders, where their customers would prepay for yarn that would only become available at a future date. They ended up getting so many preorders that in the end, only some customers got the yarn they expected; others received yarn but the yarn didn’t look like what had been advertised; many others never received anything. I’m sure we can all imagine what happened next. Yikes!

This is not at all the experience I want to have or provide for anyone, so early on I decided to use a “ready to ship” approach only. This means I’ll only post for sale what I actually have in stock. Probably, there will be times when the store has nothing available in it until I can restock. My hope is that customers will be understanding that I’m just starting out, so there’s only me to do all the dyeing, all the packing, all the shipping, plus marketing, photos, social media, etc—while still holding down a 40 hour per week day job and maintaining some kind of personal life to boot! Whew! It’s a lot to take on, but I feel like I can do it so long as I stay true to a slow approach. I also plan to be up front with everyone about things that are going on. I think that’s fair.

Many of the important behind-the-scenes things on the “to do” list have been taken care of at this point. Some of the more visible checked off items include being listed as a brand on Ravelry. I’ve also set up a couple of accounts on social media: follow Incyanity on Instagram or Twitter. Of course, my main focus is on this website so the RSS feed (or subscribing via email using the comment form at the end of any post) is the best bet so you never miss an update. For the Facebook fans out there, I did try setting Incyanity up on Facebook but unfortunately was immediately locked out due to supposed “suspicious activity”. At some point I’ll look into whether there’s anything I can do to fix that. Last but not least I created a Discord community that you can join to talk about yarn, gaming, writing, photography, and art with me and other fans of my website. I hope to see you there!

Experiments

June and July were all about experimenting with dye, digging around in my photo archives for suitable pictures to use, practicing taking clear photos of yarn, learning how to retwist hanks, figuring out layouts for the yarn product collages, and so much more.

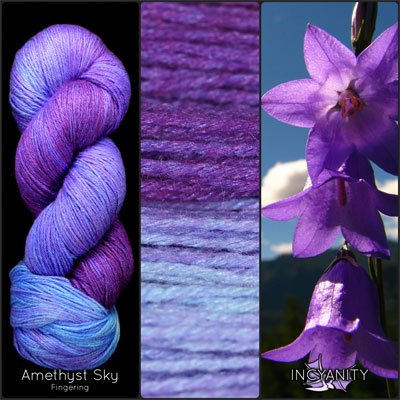

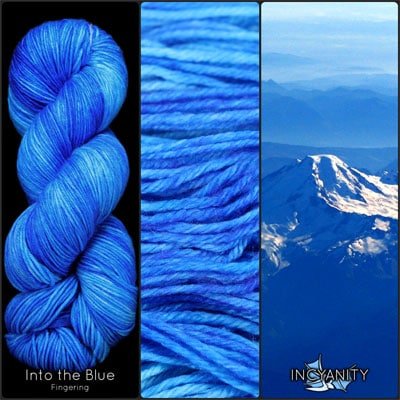

The collages in particular have had dozens of iterations representing I don’t know how many hours of work in Photoshop. At first I started out with a rectangular collage but then realized—of course—the thumbnails on Ravelry are squares. Everything had to be done over again. Once I had that fixed, figuring out how to best showcase the photo I’d chosen to create the colorway from, as well as the yarn itself, was a matter of trial and error. A lot of trial and error. Just when I thought I’d finally figured it out, there’d be something else, so the cycle would begin again! Thankfully, I’ve finally settled on something I like.

Something I want to do once I’m established is introduce an official Incyanity colorway. To do that, I need the right shade of cyan. The teal dye I have, straight out of the jar, is quite green (as shown in the left-hand hank in the picture). That’s still a lovely color but not what I want for the site’s colorway. Thankfully, I got lucky: my first try adding just a bit of blue resulted in a shade I’m quite pleased with! The actual Incyanity colorway won’t be a semi-solid like that though; I still have more experimentation to do to get exactly what I envision.

Something else I experimented with a bit more was making the same colorway on different yarn bases. That blue and purple yarn in the small square image at the start of this post? That’s a pastel version of Amethyst Sky. Based on feedback I’ve had from a few people, Amethyst Sky looks like it might be popular. If that ends up being the case, why not offer it more widely? It never hurts to try!

Since my colorways are all based on photos I’ve taken, I’m not necessarily guaranteed to get something that matches the photo on the first try. That was the case with the experiment above. The photo I picked and the way this yarn turned out totally do not match. It counts as my first “failure”, with plenty more to come I’m sure. Once again I got lucky though: more digging through my photo archives led me to discover a totally different photo that this color combination does match. Yay! Thankfully, I kept notes on what I did that resulted in this “oops”, so now all I have to do is make sure I can do it again!

Quality Assurance

Something that was very important to me to do before I open the store was to make sure my yarn “passed inspection”. Sure, I can pet and squish it all I want, and what I’ve dyed so far certainly looks pretty and correct…but would it hold up to actually being used? What would people think when they held my yarn in their hands? There’d be no point in continuing if I hadn’t actually gotten off on the right foot with the dyeing. Some of the other horror stories I read centered around how some indie dyed yarn can suffer from really bad bleeding, or even crocking (where the color comes off the yarn while it’s being worked). Paranoid about this, I rinse and rinse and rinse, and have spent time calculating precise amounts of dye to use with the particular fiber blends I’ve chosen, but even so…

I considered taking some time to crochet with my yarn myself to check its quality, but would customers believe me if I was the only source available who said the yarn is good? What if I’d actually made some huge mistake that just wasn’t obvious to me? Also, I still have a lot on my plate and so much to do! This led me to decide it would be best to send some samples out for testing and review.

I approached three crafters whose opinions I felt would be reliable. They were sent the yarn at my expense. Their only obligation was to use it for a crocheted or knitted project (pattern of their choice) and provide an honest review of their experience. The yarn was theirs to keep regardless of any conclusions they came to.

My first hanks went to PlanetJune. June is a talented multicrafter! She crochets (I love her amigurumi patterns), knits (check out her 12 Knit Sweaters Project), and so much more. I used a number of her tutorials while I was learning to crochet and otherwise find her website to be a great resource. If you haven’t checked her out you definitely should.

June was happy to take time out to help me and has been incredibly helpful and supportive ever since. I sent her one hank of Amethyst Sky on a 70/30 blend of fingering merino/silk and the test Incyanity hank which was done on a 75/25 blend of fingering merino/nylon.

What really got me excited about working with June is not just the detailed feedback she’s given me privately so far, but also that she’s opted to use my yarn for two new original patterns she’s working on! I never expected that and it’s such a great honor considering I’m just getting started.

June’s work is still in-progress so the conclusions of her experience with my yarn aren’t available in public yet. I haven’t even seen the full extent of what she’s been working on! It’s going to be a total surprise when she’s finished and I’m really looking forward to it.

She got to work right away on a pair of fingerless gloves. Her project was the first opportunity I had to see my yarn as it was being worked up. Every time there were new photos waiting for me to look at, I squeed! It’s a thrill to see yarn I dyed being made by someone else into something they love and will use. When the first set of photos came in I ran around at work showing everyone. Look! This is being made with my yarn! OMG!! So exciting. The happies were huge.

Bamboo, being a plant fiber, doesn’t dye the same way as animal fiber does. I’m using a protein dye method which means the bamboo should be resistant to color uptake, but with this particular yarn it seems hardly noticeable. The colorway worked up so nicely!

The pattern Stargrace used is the Traveling Cable Hand Warmers by Purl Soho. The finished project page on Ravelry is here. Stargrace wrote a summary of her experience with this yarn on her website so please check that out!

The last hank I sent out for testing went to Maggie from Experiments In Crafting. Maggie is a crochet enthusiast and also helps run the Hooked On Crochet Discord server. She’s recently started a YouTube channel where she reviews yarn, posts tutorials, and also shares her adventures at fiber festivals, so she felt like a natural choice to approach for testing.

Maggie’s yarn took forever to get to her (Canada to the US via Canada Post) so this was a great example of how important it is to use a reliable shipping vendor that won’t cost a small fortune while still delivering in a timely fashion. I was pretty embarrassed about how long delivery took. For a while I was worried the hank would never arrive!

I sent her a hank of Into the Blue, a fingering weight 75/25 blend of merino/nylon. The photo this colorway is based on is one of the first photos I knew I wanted to use when I started dyeing.

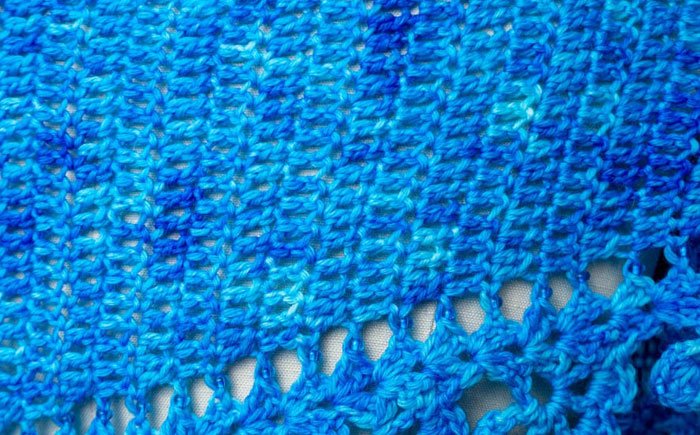

Although Maggie received her yarn after June and Stargrace, her project was actually the first one to be fully completed! She chose to use this lovely Cherokee Rose shawl pattern by Ambur Hsiao to test with.

Honestly, when I saw her project photos I got pretty choked up.

Seeing this finished item draped so nicely around the mannequin and then photographed professionally like this really hit me in all the best ways. Any doubts I still had about being able to dye nice yarn went out the window. I mean, wow! Just look at that!

Other than some minor bleeding on this colorway and a couple of spots that might be too heavy with dye, Maggie said she enjoyed working with my yarn and had no complaints. Her finished project page on Ravelry is here.

I am really glad I took this step! The reassurance is a tremendous confidence boost and it’s great to have other sources that can offer testimony to the quality of my yarn as I move forward. Thanks to June, Stargrace, and Maggie for their time!

Challenges

One of the yarn bases I initially ordered was a 70/30 merino/silk blend. I have some silk yarn (a different blend) from another dyer that I quite like. Silk is a gorgeous and luxurious fiber—who wouldn’t want to wear it if given the chance? 70/30 was available from the supplier I had chosen to work with first and I had high hopes. Those hopes were dashed when I received the yarn. The blend didn’t meet my expectations; it didn’t feel like it had any silk in it at all, to be quite honest. The merino/nylon and merino/bamboo blends were both much nicer than the silk blend. Had I been sent the wrong stuff? I double-checked. Nope, I was sent what I ordered. Not only was it just not very nice in the way I expected but when I soaked it for the first time…it was dirty too. You know the milky white water you get from rinsing rice? The water from this yarn was dirty like that. Ew! Maybe I got a bad batch? Either way, even after I washed it, the silk softness I expected just wasn’t there. (I mentioned this to June when I sent her the 70/30 hank to test, and that I wouldn’t be keeping that specific base but it should still be a representative example of my dyeing ability.)

I found a 50/50 silk blend from a different supplier and ordered that instead. Thankfully, this yarn does meet my expectations (and is clean!) so I’ll be keeping the base. But? The first skein I dyed tangled despite having multiple ties in it so now I worry that the other skeins will tangle too. I have a niddy noddy so (after many hours of patience) I was able to re-skein the hank. Problem is, the re-skeined hank isn’t the same size as the original one was, so the colored sections of the yarn no longer line up the way they did when the hank was dyed originally (doesn’t match the product photo for the colorway). That bothers me because a customer might think what they bought and what they received isn’t the same. I decided I’ll have to put a note with that one that it had to be re-skeined, but in general, I’ve started wondering if I should re-skein every hank of yarn I received before I dye it, just in case they’re all tangled (or even if they aren’t but end up tangled during dyeing and I have to re-skein again…they’d still come out looking correct with the same skein size). Truth be told, I’m not keen on the idea because of the extra time it will take to do it. On the other hand, I can’t send tangled yarn to customers either! I’ll need to see if any others from this supplier seem prone to tangling once I’m able to dye more of them.

Another recent challenge: this past weekend, my camera basically kicked the bucket. It had been giving me some problems previously with shutter misfires and things like that while trying to shoot the yarn, but the full shutter failure from this weekend means it’s on its last legs. I did get it functioning again, but for how long? I’m travelling later this week on business to a location that could also prove incredible for potential colorway shots. I actually arranged with my employer to leave early on the trip for exactly that reason (to have extra shooting time). But with my camera in this state I can’t just hope for the best—with my luck I’ll get out there and the thing won’t work at all. That means an expensive trip to the camera store in the next few days…

My biggest challenge since the end of July has been getting the rest of the yarn I have on hand dyed and ready. I had hoped to be able to have the store open by the end of August, but August had other plans for me. I had two weeks of vacation at the start of the month which should have been plenty of time to dye a whole whack of yarn! What happened instead? A few things, much of it Very Important Personal Stuff, but what stood in my way the most was having to take care of the two dogs my parents own (they were more of a handful than I expected), super warm temperatures, and the forest fire smoke from BC getting really bad.

I drive a black car so have been acutely aware of just how much ash has been in our air. It has gotten into everything no matter how careful I’ve been to keep windows closed and such. I worried that smoke particles would become bound to the yarn fibers during the dye process and carry their sooty stench with them. Everything else has smelled like old acrid campfire and it also got into everything—hair, clothes, you name it, so why not the yarn too? Calgary had air quality alerts and some days our eyes were burning (even indoors). Even though rinsing is part of the dye process I just didn’t want to risk it. Nobody wants gross, smelly yarn, so my stuff stayed wrapped up in plastic bags. That put me behind by about two weeks.

The smoke started to clear and the daytime temperatures became more reasonable after I went back to work, so I planned to catch up. But then my mom had a pretty bad accident that left all of us shaken. She’s fine now and mending well, but for another week I needed to concentrate on her. Then suddenly it was month-end, and some other personal things came to the forefront, and work got crazy again. Now it’s the start of the second week of September and I honestly am not really sure where the time went! Even if I do get to take pictures on my trip this month that I can turn into colorways, that’s still time away from actual dyeing. In October I’m travelling again, too.

I have a lot on my plate and a lot of what’s there is really important in ways I can’t talk about just now (but soon™). This Life Stuff has to take precedence over yarn. So, it might be November before the store is open, though if I get a chance to do it (properly!) before then, then I will. Please bear with me! Thanks to everyone for their support, and in the meantime, happy hooking. :)

Yarn Shop Changes for 2021 Part Two

Hello fellow yarnists! It’s been a while since I posted a shop update, so here we go! First, s

A New Venture: Incyanity Yarn!

On June 28, 2020, Incyanity was rebranded as aka Iron Dragon. Read the announcement. I have a lot of

Yarn Shop Open for Business!

On June 28, 2020, Incyanity was rebranded as aka Iron Dragon. Read the announcement. That’s ri

This site uses Akismet to reduce spam. Learn how your comment data is processed.

Leave a Reply